Categories: Tray TC-ER / VFD Cable , Flexible Double Shielded Motor Connecting Cable

9YSLCYK-JB+3

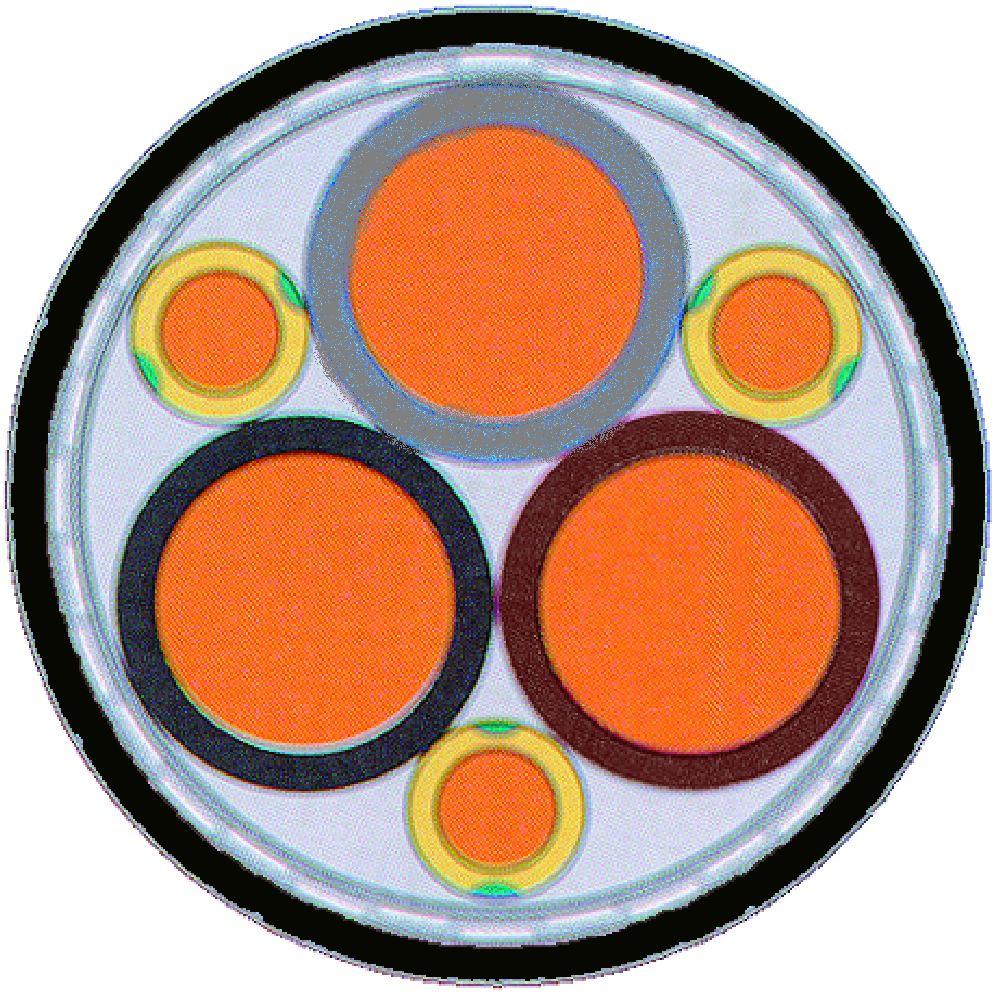

9YSLCYK-JB+3 is a double shielded, large gauge size, PVC motor supply cable with a black PVC UV-resistant outer jacket and three (3) symmetrical ground wires.

Sku: 905

- Description

- Specifications

- Product Details

Product Description

9YSLCYK-JB+3 is a double shielded, large gauge size, PVC motor supply cable with a black PVC UV-resistant outer jacket and three (3) symmetrical ground wires. Polypropylene insulation over a very fine copper strand provides a low-loss transfer of power, excellent low capacitance performance and superior flexibility when compared to conventional PVC cables. 9YSLCYK-JB+3 applications include frequency converters, motor runs and in connections with high electromagnetic interference. Found in the automotive, paper and food industry, environmental technology, packaging industry, machine tools and handling equipment. The overall foil and tinned copper braid shield offer excellent protection against electromagnetic and electrical interferences. This version substitutes the common single green/yellow ground wire for three (3) symmetrical green/yellow ground wires for improved EMC characteristics. For medium mechanical stresses found indoors in dry, moist or wet areas. The black UV-resistant jacket allows for outdoor use and for direct burial applications.should be used in outdoor applications.

Product Specifications

Construction:

- Fine bare copper strands

- Strands to VDE-0295 class.5, IEC 60228 Cl-5

- Special polypropylene (PP) core insulation

- Color code VDE-0293-308 (HD 308 S2)

- Three (3) symmetrical green/yellow grounds

- Aluminum foil wrapping over cores

- 85% tinned copper braid shield

- Special black PVC outer jacket (RAL 9005)

- UV-resistant and direct burial approved

- Extremely oil & chemical resistant

Technical:

- Working voltage IEC: 600/1000 volts

- Working voltage UL/CSA: 1000 volts

- Testing voltage: 4000 volts

- Flexing bending radius: 15 x Ø

- Static bending radius: 4 x Ø

- Flexing temp: -5º C to +80º C

- Static temp: -40º C to +80º C

- Flame retardant: IEC 60332.1, VW-1

- Insulation resistance: 200 MΩ x km

Approvals:

- UL AWM 2570 or 20886, VW-1

- CSA AWM I/II A/B, FT-1

- UL/CSA rated 1kV 80 Deg C.

- Adapted to VDE 0276, 0250 & 0207

- CE Low Voltage Directive 2014/35/EU

- RoHS compliant

Product Details

| Part Number | Cores | Nominal OD (in) | Nominal OD (mm) | CU LBS/MFT | WT LBS/MFT | AMPs | GRND x 3 |

| 1 AWG (400/26) 50,0mm2 | |||||||

| 9050103 | 3 | 1.224” | 31.1mm | 1446 | 1609 | 168 | 8 AWG |

| 2 AWG (280/26) 35,0mm2 | |||||||

| 9050203 | 3 | 1.083” | 27.5mm | 1030 | 1152 | 135 | 10 AWG |

| 4 AWG (200/26) 25,0mm2 | |||||||

| 9050403 | 3 | 0.957” | 24.3mm | 808 | 889 | 108 | 12 AWG |

| 6 AWG (128/26) 16,0mm2 | |||||||

| 9050603 | 3 | 0.787” | 20.0mm | 504 | 549 | 82 | 14 AWG |

| 8 AWG (80/26) 10,0mm2 | |||||||

| 9050803 | 3 | 0.685” | 17.4mm | 343 | 413 | 61 | 16 AWG |

| 10 AWG (84/28) 6,00mm2 | |||||||

| 9051003 | 3 | 0.598” | 15.2mm | 185 | 282 | 44 | 17 AWG |

| 12 AWG (56/28) 4,00mm2 | |||||||

| 9051203 | 3 | 0.535” | 13.6mm | 150 | 217 | 34 | 18 AWG |

| 14 AWG (50/30) 2,50mm2 | |||||||

| 9051403 | 3 | 0.508” | 12.9mm | 87 | 148 | 26 | 20 AWG |

| 16 AWG (30/30) 1,50mm2 | |||||||

| 9051603 | 3 | 0.449” | 11.4mm | 59 | 94 | 18 | 24 AWG |

| 2/0 AWG (356/24) 70,0mm2 | |||||||

| 9052103 | 3 | 1.461” | 37.1mm | 1999 | 2050 | 207 | 8 AWG |

| 3/0 AWG (485/24) 95,0mm2 | |||||||

| 9053103 | 3 | 1.575” | 40.0mm | 2651 | 2792 | 250 | 6 AWG |

| 4/0 AWG (614/24) 120,0mm2 | |||||||

| 9054103 | 3 | 1.677” | 42.6mm | 3244 | 3403 | 292 | 6 AWG |

| 300 MCM (765/24) 150,0mm2 | |||||||

| 9053003 | 3 | 1.969” | 50.0mm | 3630 | 4110 | 335 | 4 AWG |

| 350 MCM (944/24) 185,0mm2 | |||||||

| 9053503 | 3 | 2.189” | 55.6mm | 4747 | 5245 | 382 | 2 AWG |